High Speed Film Blowing Machine

This machine is used to for plastic film blowing, like low density polythene(LDPE), high density polythene(HDPE), linear low density polythene(LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag,vest bags and etc.

Description

Use

This machine is used to for plastic film blowing, like low density polythene(LDPE), high density polythene(HDPE), linear low density polythene(LLDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag,vest bags and etc.

Main Technical Parameter

|

Model |

SJ-B55 |

SJ-B50 |

SJ-B60 |

SJ-B65 |

|

Screw Diameter |

55mmhigh speed screw |

50mm High Speed Screw |

60mm High Speed Screw |

65mm High Speed Screw |

|

Screw Ratio(L/D) |

32:1 |

32:1 |

32:1 |

32:1 |

|

Die Size(high speed straight die) |

HDPE:80mm, or LDPE:150mm |

HDPE:60mm or LDPE:100mm high speed straight die |

HDPE:φ100mm, LDPE:φ200mm high speed die |

HDPE:150mm, LDPE:280mm high speed die |

|

Gearbox(with oil pump) |

180 |

173 |

200 |

200 |

|

Temperature Control Zone |

6 zones |

5 zones |

7 pieces |

7 pieces |

|

Heating Power |

18kw |

15kw |

7 zones |

7 zones |

|

Main Motor |

30kw with inverter control |

22kw |

22kw |

30kw |

|

Take-up Motor |

1.5kw with inverter control |

1.5kw with inverter |

1.5kw with inverter control |

1.5kw with inverter control |

|

Max. Extrusion output |

HDPE: 60kg/hr LDPE:80kg /hr (related with film thickness and width) |

HDPE: 40kg/hr LDPE:60kg /hr |

HDPE: 65kg/hr LDPE:100kg /hr (related with film thickness and width) |

HDPE: 70kg/hr LDPE:110kg /hr |

|

Max. Folding Width of Film |

800mm |

600mm |

1000mm |

1200mm |

|

Single-sided Thickness of Film |

0.008 -0.10mm |

0.008 -0.10mm |

0.01 -0.10mm |

0.01 -0.10mm |

|

Voltage |

3Phase 4Line 380V 50Hz |

3Phase 4Line 380V 50Hz |

3Phase 4Line 380V 50Hz |

3Phase 4Line 380V 50Hz |

|

Machine Weight |

About 2000kg |

About 1800kgs |

About 2500kg |

About 2500kg |

|

Overall Dimensions(L×W×H) |

5500×2800× 4600mm |

5400×2600× 4200mm |

5700×3700× 5000mm |

5900×3300× 5500mm |

Specifications

1. With good hardness,corrosion resistanceand specially-designed screw, higher output and good plasticizing quality.

2.Main motor and take-up motor are controlled by frequency inverter

3. With pneumatic cylinder system to adjust the gap of traction roller

4. Material of screw and barrel: alloy steel with water jacket

5. Gear box: Surface heat quenching and tempering/auto. Oil lubricated

6. Die material: steel 45#/surface treatment of flow channel: hard chrome- plating

7. Digital display temperature controller

Certificates:

If need more details, please contact

Fern Chen

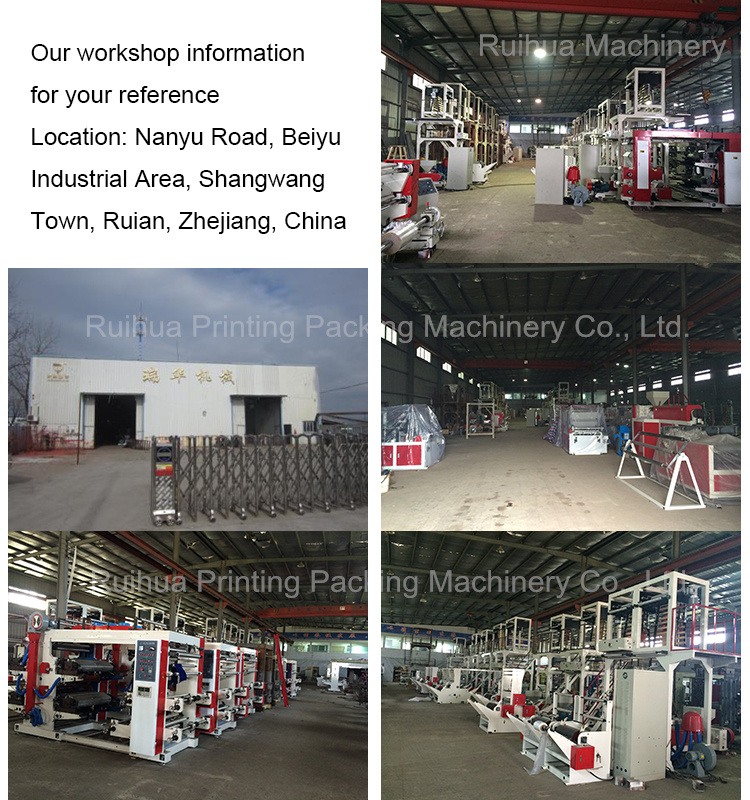

Ruian Ruihua Printing Packing Machinery Co.,Ltd.

Address: 18# Xingwang Industrial Park, NO. 3555 Jingang Road, Ruian City, Zhejiang Province, China

Mob: +86 18957702100

Whatsapp/Viber/Wechat: +86 18958856105

Web.: www.raruihua.com/www.ruihuamachinery.com

Leave Message

Leave Message

Your privacy is important to us - we never sell or share your information.

-110053.jpg)

--111208.jpg)