Roll Feeding Paper Bag Making Machine

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper, side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming

Description

Introduction

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper, side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PLC programmable servo motor through the human-machine touch screen interface. It can produce several of specifications paper bags. This machine has advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

Features

1. RHD-350 Bag width Range:120-350mm

2. Material lifting adopts pneumatic lift structure.

3. Global initiative, leading technology, the real automatic constant tension control system, using the United States Bellofram constant precision pressure regulator, tension from start to finish no less.

4. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life

5. Adjustable into cylinder template synchro control structure, save template cost, easy and quickly adjustment.

6. Thumb buttons, appressed bottom cutting device, bag type have many choices.

7. Thumb mouth and appressed bottom cutting position does not stop cutting position synchronous adjusting structure, adjust the more direct, more convenient.

8. Don't stop machine adjusting indentation position structure, indentation position adjustment will be a very convenient things.

9. Don't stop machineclampthe wheel hub side, suction nozzle synchro control structure, adjust the side clips will become very simple and fast.

10. Don't stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple,more time saving.

11. Glue roller air defense coating control, avoid gluing on besmear brushs hub surface directly, reduce unnecessary trouble.

12. Accurate color tracking system, color errors automatically shut down

13. Automatic lubricating oil supply system

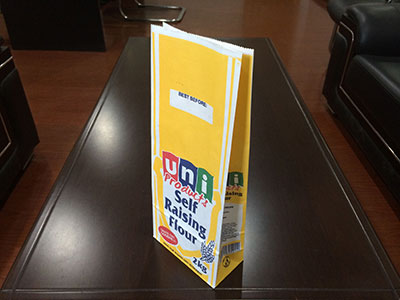

The bag samples which the machine can make are below

|

|

|

|

Main Technical Parameter(see picture above)

|

(W) Bag Width |

120-350 mm |

|

(L) Bag Length |

250-480 mm |

|

(H) Bottom Size |

70-150 mm |

|

(C) Bag tube length |

290-580 mm |

|

Max. Speed |

150 pcs/min |

|

Max. reel weight |

700 Kg |

|

Max.Roll diameter |

1200 mm |

|

Reel inner diameter |

76 mm |

|

Paper specification |

80-150 gsm |

|

Electric |

50Hz, 3 phase, 4 line, 380V |

|

Air pressure |

≥0.3cmm, 0.6~1.2Mpa |

Fern Chen

Ruian Ruihua Printing Packing Machinery Co.,Ltd.

Address: 18# Xingwang Industrial Park, NO. 3555 Jingang Road, Ruian City, Zhejiang Province, China

Mob: +86 18957702100

Whatsapp/Viber/Wechat: +86 18958856105

Web.: www.raruihua.com/www.ruihuamachinery.com

Leave Message

Leave Message

Your privacy is important to us - we never sell or share your information.

-141855.jpg)

-141852.jpg)

--141849.jpg)